Surge Protection in Industrial Control Panels

Electrical surges are an often underestimated risk in industrial environments. They can occur suddenly, travel through power and data lines, and damage sensitive components inside control panels before anyone realises there is a problem. For facilities that rely on automation, understanding surge protection is an important part of maintaining reliability, safety, and compliance.

Surge protection is not just about protecting equipment from lightning strikes. It also guards against everyday electrical disturbances that can disrupt operations or cause gradual damage over time. When considered alongside wider machine safety systems, surge protection becomes a key element of a resilient control panel design.

What causes an electrical surge?

Surges are brief spikes in voltage that exceed normal operating levels. They can be caused by external events such as lightning or faults on the power network, but they are just as often created internally. Large motors switching on and off, welding equipment, or sudden load changes can all introduce transient voltages into a system.

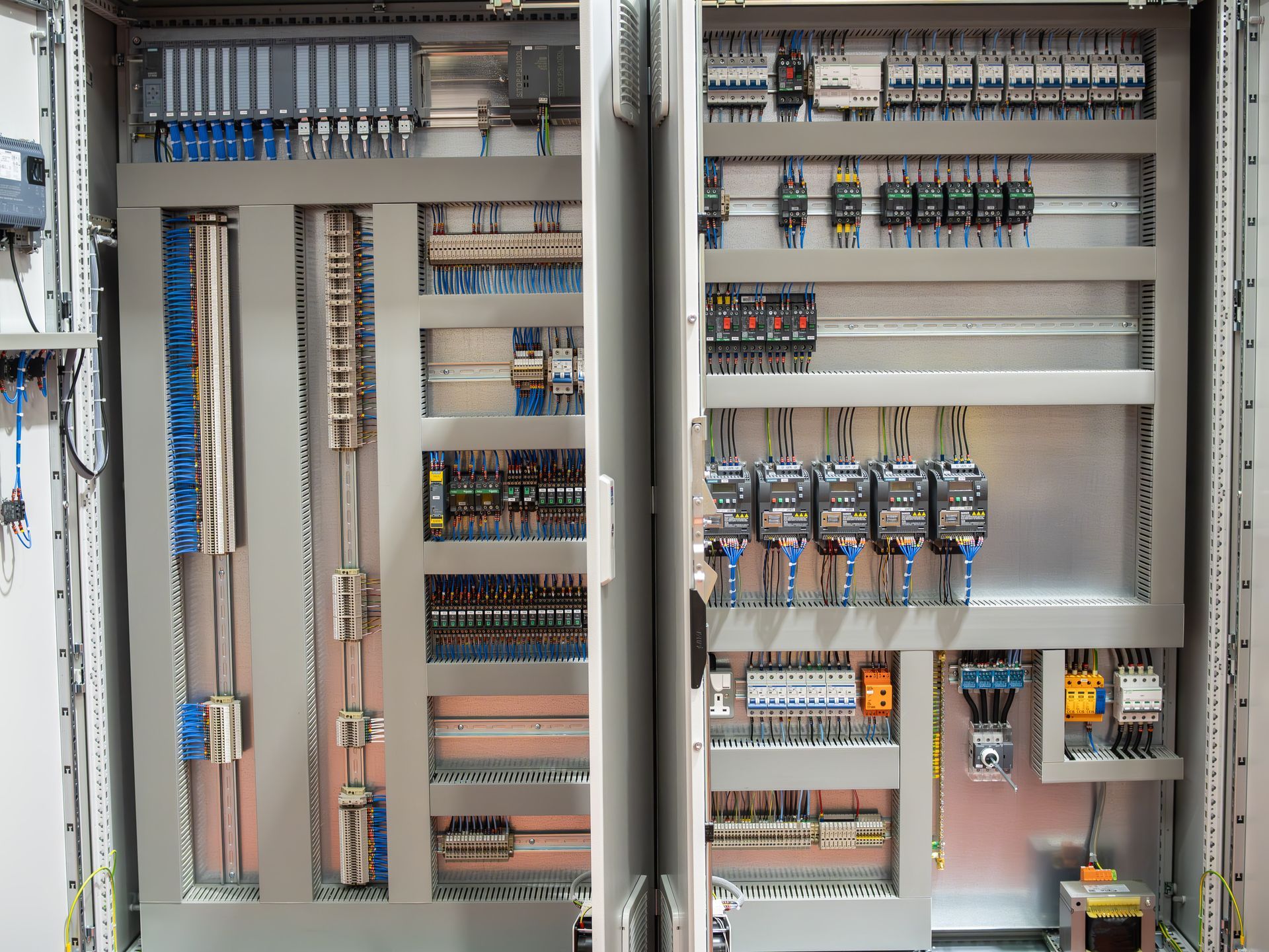

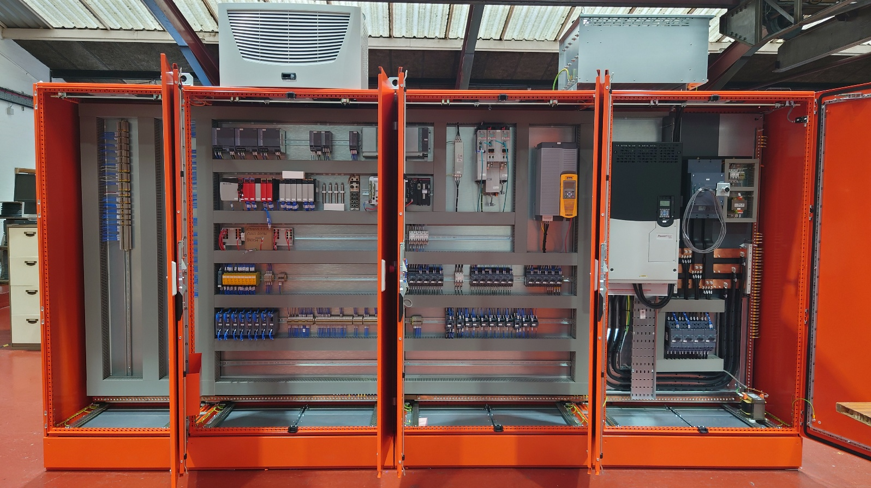

In industrial control panels, these spikes can affect programmable logic controllers, sensors, communication modules, and safety devices. Even small, repeated surges can shorten the lifespan of components and lead to unpredictable behaviour.

Why are control panels particularly vulnerable?

Control panels bring together power distribution, control logic, and communication systems in one enclosure. This concentration of sensitive electronics means that a single surge can affect multiple parts of a process at once. In safety critical applications, this can lead to machine stoppages or unsafe conditions.

Surge protection helps maintain the integrity of machine safety solutions by ensuring that safety relays, emergency stop circuits, and monitoring systems continue to operate as intended. Without proper protection, these systems may fail silently or trigger false faults.

How do surge protection devices work?

Surge protection devices, often referred to as SPDs, are designed to divert excess voltage away from sensitive equipment. They act as a controlled path to earth when a surge occurs, limiting the voltage that reaches connected components.

Different types of SPDs are used depending on where they are installed. Some are designed for incoming power supplies, while others protect signal and data lines. In well-designed panels, surge protection is layered so that large external surges are reduced first, followed by finer protection closer to critical electronics.

How is surge protection integrated into safety focused design?

Surge protection should be considered early in the design process rather than added as an afterthought. Panel layout, earthing arrangements, and cable routing all influence how effective protection will be.

When integrated properly, surge protection supports the reliability of machine safety systems by reducing the risk of unexpected failures. This is especially important in automated environments where systems are expected to operate continuously with minimal supervision.

Standards and guidance related to machine safety often emphasise the need for robust electrical design. Surge protection plays a role in meeting these expectations by addressing risks that are not always visible during normal operation.

What are the maintenance and inspection considerations?

Like many protective components, surge protection devices have a finite lifespan. Each time they absorb a surge, a small amount of their capacity is used. Over time, this means they may need replacement even if no obvious fault has occurred.

Regular inspection and maintenance schedules should include checks on surge protection status indicators where fitted. This helps ensure that machine safety solutions remain effective throughout the life of the control panel.

How is operational reliability impacted?

Beyond safety, surge protection contributes to overall operational stability. Reduced equipment damage means fewer unplanned shutdowns and less time spent diagnosing intermittent faults. This is particularly valuable in environments where downtime is costly or disruptive.

For businesses investing in automation, surge protection supports long term performance and helps protect the investment made in control hardware and software.

Surge protection is not about eliminating every electrical risk, but about managing it sensibly. By understanding where surges come from and how they affect control panels, businesses can take informed steps to protect their systems.

When combined with thoughtful design, good earthing practices, and regular maintenance, surge protection strengthens the resilience of industrial automation. It is one part of a broader approach to safe and dependable operation, working alongside well engineered machine safety systems to support consistent performance.

FAQs

What is the main purpose of surge protection in control panels?

It limits the voltage that reaches sensitive components during electrical surges, reducing the risk of damage and malfunction.

Are power surges only caused by lightning?

No, many surges are created internally by equipment switching, motors, or changes in electrical load.

Do all industrial panels need surge protection?

Most panels benefit from it, especially those containing electronics that support automation or safety functions.

How often should surge protection devices be checked?

They should be inspected as part of routine maintenance, with attention to any status indicators or manufacturer guidance.

Does surge protection replace other safety measures?

No, it complements other machine safety solutions by addressing electrical risks alongside mechanical and control based protections.