Can Automation Reduce Downtime in Manufacturing?

Downtime is a costly challenge within the world of manufacturing. Every minute that production stops can affect output, delivery schedules, and overall profitability. While some delays are unavoidable, many manufacturers are now turning to automation and control systems to minimise disruption and improve resilience. With technology advancing rapidly, automation is no longer just about efficiency, but is becoming a core strategy for reducing downtime and creating more reliable production environments.

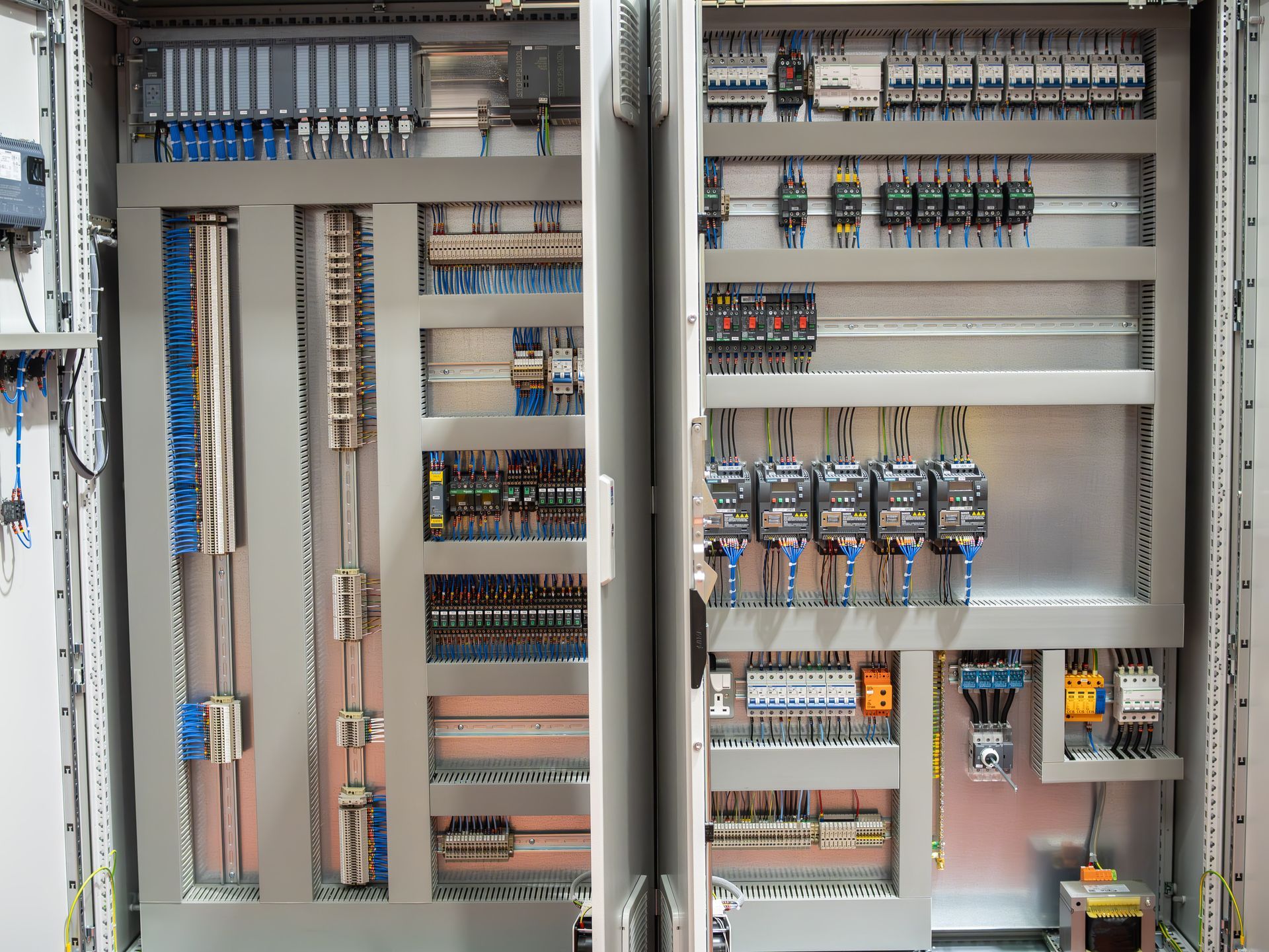

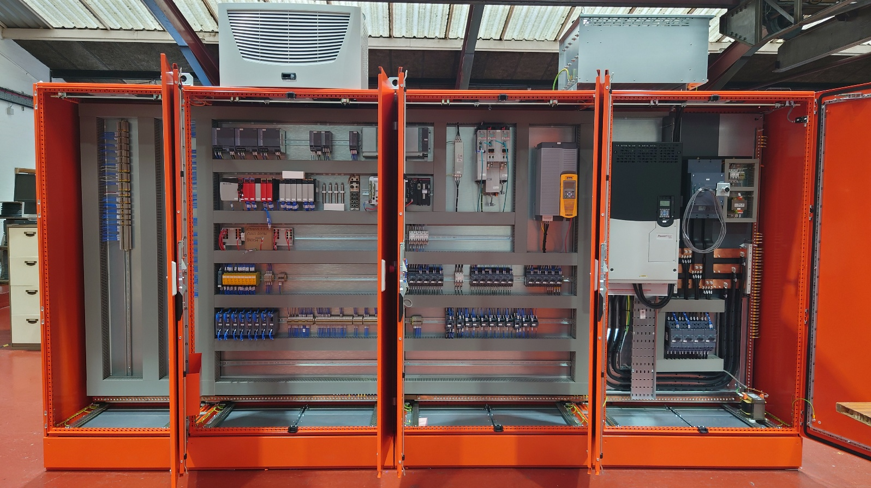

Modern industrial control panels are designed to monitor equipment, streamline processes, and support decision making in real time. By improving visibility and reducing manual intervention, these systems can help manufacturers predict problems before they occur and respond more quickly when issues arise.

Improved monitoring and early fault detection

One of the most effective ways that automation reduces downtime is through better monitoring. Automated systems can collect data continuously from sensors, motors, conveyors, and other key components. This constant flow of information allows manufacturers to identify early signs of wear, overheating, or unexpected behaviour.

Instead of waiting for a machine to fail, engineers can intervene at the right moment and carry out maintenance before the issue escalates. Predictive maintenance supported by automation and control systems helps prevent unplanned stoppages and keeps production running smoothly.

Greater consistency and fewer human errors

Human error remains a common cause of downtime. Even skilled staff can occasionally press the wrong button, misread a gauge, or overlook a detail during a busy shift. Automation helps to eliminate many of these risks by taking over repetitive or precision-based tasks.

When processes are handled by industrial automation control systems, they follow the same sequence every time. This consistency reduces mistakes, ensures product quality, and limits the number of disruptions caused by manual handling. Staff can focus on supervision and problem solving rather than tasks that could lead to errors under pressure.

Streamlined changeovers and production flexibility

In many manufacturing environments, changeovers between product types or batches can cause delays. Manual adjustments, tool changes, and recalibration all take time. Automated systems can store multiple production settings and switch between them quickly, reducing the time needed to prepare for the next run.

This flexibility allows manufacturers to react more easily to customer demand without sacrificing productivity. Faster changeovers lead to fewer interruptions and more efficient use of machinery.

Improved safety and reduced stoppages

Safety related stoppages can cause significant downtime, especially when equipment needs to be shut down for inspections or incident investigation. Automation can help reduce these events by ensuring that machines operate within safe parameters at all times.

Sensors, interlocks, and automated shutdown mechanisms protect both operators and equipment. If a problem is detected, automated systems can respond instantly, preventing further damage and reducing the length of the stoppage. Over time, this proactive approach creates a safer workplace with fewer unplanned halts.

Better integration across the production line

Automation is not just about individual machines. When multiple processes communicate with one another, production becomes more coordinated and predictable. Integrated automation and control systems allow conveyor lines, packaging equipment, filling machines, and inspection tools to work together smoothly.

If something slows down in one area, the system can adjust automatically to prevent a backlog. This level of coordination reduces bottlenecks and keeps the entire line moving efficiently.

Is automation always the answer?

While automation offers clear advantages, it is not a one size fits all solution. Smaller facilities with very simple production tasks may not need a full automated setup. However, for most manufacturers experiencing repeat stoppages or inconsistent output, even partial automation can make a meaningful difference.

Working with specialists in industrial automation controls can help businesses identify which processes will benefit most and create a tailored approach that supports long term reliability.

FAQs

How does industrial automation help reduce downtime?

Automation helps by monitoring equipment, preventing human errors, improving changeovers, and ensuring processes run consistently.

Can industrial automation controls predict equipment failures?

Yes. These systems collect real time data and identify early signs of wear or malfunction before they cause a breakdown.

Does automation improve workplace safety?

Automated sensors and safety controls can reduce accidents and prevent damage, leading to fewer safety related stoppages.

Is automation suitable for all manufacturers?

Not always. Smaller businesses may only need partial automation, but most benefit from improved efficiency and reliability.

Can automation be added to an existing production line?

Yes. Many automation solutions are designed to integrate with existing machinery and improve performance without complete replacement.