Can Control Panel Design Impact Operational Costs?

When businesses think about reducing operational costs, they often focus on energy use, staffing, or maintenance schedules. One area that is sometimes overlooked is control panel design. Yet the way a control panel is planned, built, and laid out can have a lasting effect on efficiency, reliability, and long-term running costs. Understanding how design choices influence day to day operations helps organisations make more informed decisions from the outset.

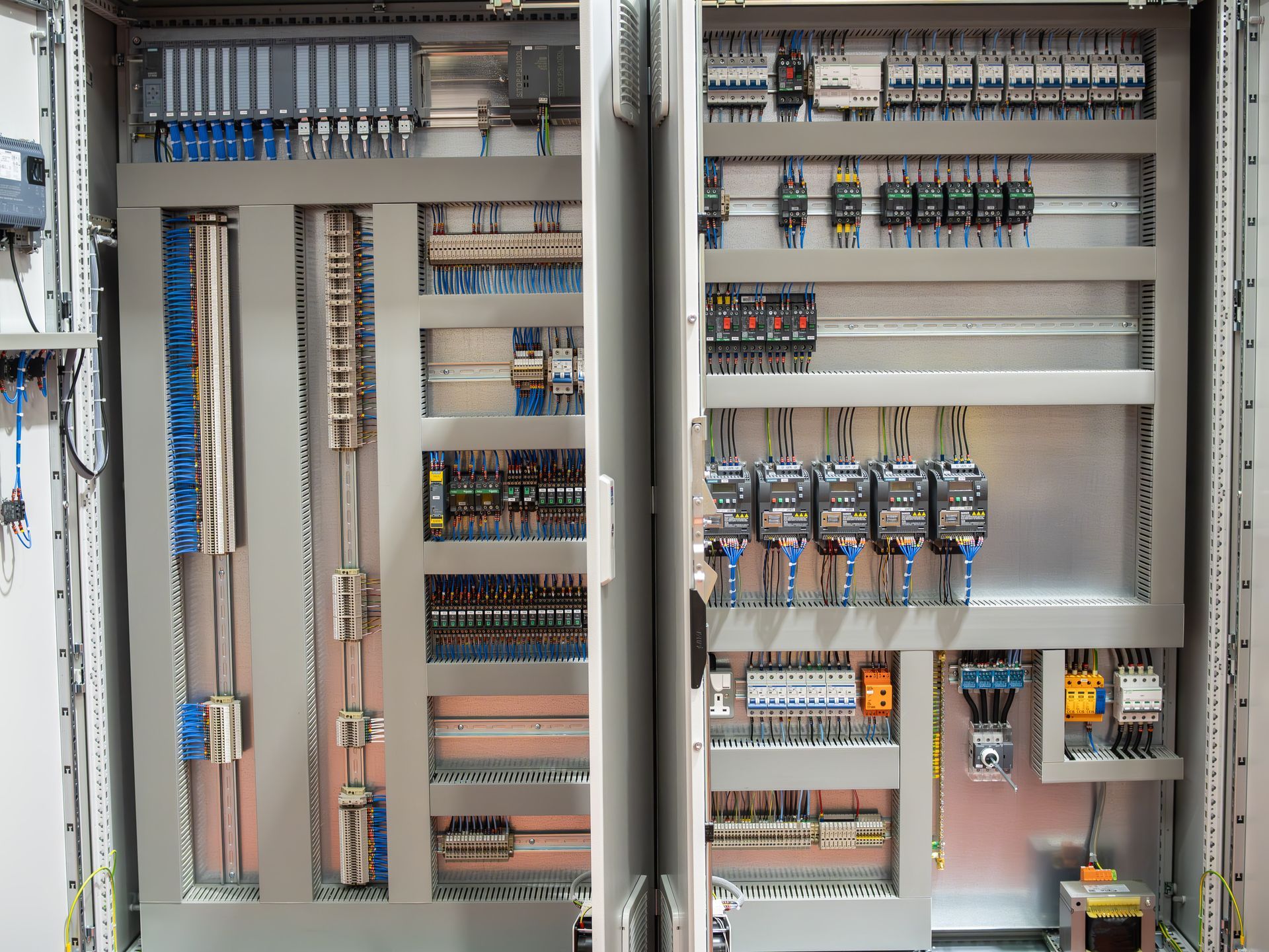

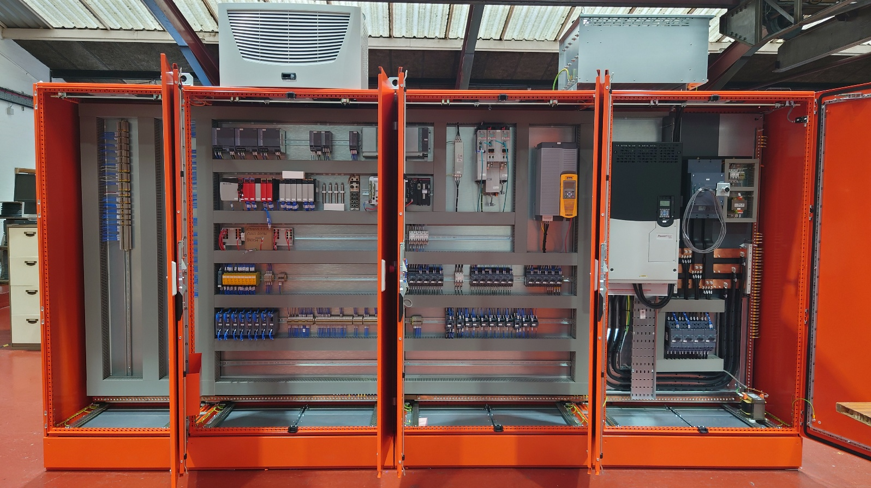

Control panels act as the central hub for machinery and automation systems. They house components that manage power distribution, control logic, safety systems, and communication between machines. The quality of control panel board design affects how smoothly these systems operate and how easily they can be maintained over time.

Design and energy efficiency

Energy consumption is a major operational cost in many industrial environments. Control panel design plays a role here by influencing how efficiently equipment is powered and controlled. Poor layout or incorrect component selection can lead to unnecessary heat build-up, voltage drops, or inefficient switching. Over time, this can increase energy usage and place additional strain on components.

Well considered design ensures components are sized correctly and arranged to allow proper airflow. This reduces overheating and helps systems run closer to their optimal efficiency. For businesses operating multiple machines, even small improvements in energy efficiency can add up to noticeable savings.

Maintenance and downtime

Downtime is often one of the most expensive issues a business may face. When a machine stops unexpectedly, production slows or halts completely. The ease with which faults can be identified and resolved is closely linked to control panel layout.

Clear labelling, logical wiring routes, and accessible components all make maintenance quicker and safer. Good control panel board design allows engineers to diagnose problems without unnecessary disassembly. This reduces labour time and helps get equipment back online faster.

Control panel manufacturers who prioritise serviceability in their designs help businesses avoid prolonged downtime and reduce reliance on specialist callouts.

Installation and future expansion

The initial installation phase also affects costs. Panels that are poorly designed may require additional on-site adjustments, extended commissioning time, or rework. This increases installation costs and delays project completion.

A well-designed panel anticipates future needs. Allowing space for additional components or upgrades can reduce the cost of expansion later on. Businesses often evolve, adding new machinery or adapting processes. Panels that are designed with flexibility in mind make these changes simpler and more cost effective.

Component lifespan and replacement costs

Heat, vibration, and electrical stress all affect component lifespan. Poor panel design can expose components to harsher conditions than necessary, leading to premature failure. Replacing components frequently increases maintenance costs and raises the risk of unplanned downtime.

Thoughtful layout, correct spacing, and appropriate cooling help extend component life. Over the lifespan of a system, this can significantly reduce replacement costs and improve reliability.

Compliance and safety considerations

Non-compliant panels can lead to costly consequences, including fines, rework, or forced shutdowns. Designing panels in line with relevant standards from the start avoids these risks. Safety focused design also reduces the likelihood of accidents, which can have serious financial and operational implications.

Experienced control panel manufacturers understand regulatory requirements and incorporate them into the design process. This ensures panels are safe, compliant, and suitable for their intended environment.

The value of informed design decisions

While a well-designed control panel may cost more initially, it often delivers lower total cost of ownership. Reduced energy use, faster maintenance, longer component life, and easier expansion all contribute to savings over time.

For businesses assessing automation investments, control panel design should be viewed as a strategic decision rather than a technical detail. The right approach supports reliable operation and predictable costs throughout the system’s life.

FAQs

Can poor control panel design really increase running costs?

Yes, inefficient layouts can lead to higher energy use, more frequent faults, and longer maintenance times.

How does control panel design affect maintenance?

Clear wiring, good labelling, and accessible components reduce the time and cost required for repairs.

Is it worth investing more in design at the start?

Often yes. Better design can lower long term costs by improving reliability and reducing downtime.

Can control panels be designed for future expansion?

Yes, allowing space and flexibility during design can make later upgrades far less expensive.

Who should be responsible for control panel board design?

Experienced control panel manufacturers with knowledge of standards, safety, and real world operation are best placed to manage this process.